This document also presents information on the safety analysis methods needed to conduct the safety assessment. Articles Fault Tolerance for Digital Systems. FHA results are normally shown in spreadsheet form, with columns identifying function, failure condition, phase of flight, effect, hazard classification, DAL, means of detection, aircrew response, and related information. The overall aircraft operating environment is considered. Handbooks and manuals Engineering literature.

| Uploader: | Zur |

| Date Added: | 13 October 2006 |

| File Size: | 56.65 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 28904 |

| Price: | Free* [*Free Regsitration Required] |

The SSA summarizes the residual risks remaining in the system and should show all hazards afp the failure rates. From Wikipedia, the free encyclopedia. Using qualitative assessment, aircraft functions and subsequently aircraft system functions are systematically analyzed for failure conditions, and each failure condition is assigned a hazard classification. RAM Commander Version 8.

This document also presents information on the safety analysis methods needed to conduct the safety assessment. A fault tree is prepared for each SFHA hazard rated hazardous or catastrophic.

The CCA consists of three separate types of analyses which are designed to uncover hazards not created by a specific subsystem component failure. By using this site, you agree to the Terms of Use and Privacy Policy. Best Paper Award for Dr. Other methods include dependence diagram or reliability block diagram and Markov Analysis. One approach is to identify systems by their ATA system codes and the corresponding hazards by derivative identifiers.

For example, the thrust reverser system could be identified by its ATA code ldf The next pages give an overview of the modeling techniques and how they should be applied. DALs and specific safety design requirements are imposed on the subsystems. Each hazard is assigned a unique identifier that is tracked throughout the entire safety life cycle.

A Comparison of STPA and the ARP 4761 Safety Assessment Process 1

Back to desktop version Back to mobile version. Untimely deployment of thrust reverser would zrp a hazard, which could be assigned an identifier based on ATA code The SSA may include the results of all safety analysis and be one document or may be many documents. These may include preventive or mitigation strategies selected for particular subsystems.

Guidelines and methods for conducting the safety assessment process on civil airborne systems and equipment. Introduction to Successful Prediction of Product Performance.

ARP - Wikipedia

In the case of the implementation of existing designs in a new derivation, alternate means such as service experience may be used to show compliance. Software is always included in this analysis as well as looking for manufacturing errors or "bad lot" components. Articles Fault Tolerance for Digital Systems.

The Zonal Safety Analysis ZSA looks at each compartment on the aircraft and looks for hazards that can affect every component in that compartment, such as loss of cooling air or a fluid line bursting. Subsystem failure rate budgets are assigned so that hazard probability limits can be met.

You need to have JavaScript enabled in order to access this site.

The first 30 pages of the document covers that process. A subset of this material may be applicable to non The last pages give an example of the process in action. The overall aircraft operating environment is considered. The methods outlined here identify a systematic means, but not the only means, to show compliance.

FHA results are coordinated with the system design process as aircraft functions are allocated to aircraft systems. The PSSA may contain qualitative FTA, which can be used to identify systems requiring redundancy so that catastrophic events do not result from a single failure or dual failure where one is latent.

[PDF] A Comparison of STPA and the ARP Safety Assessment Process 1 - Semantic Scholar

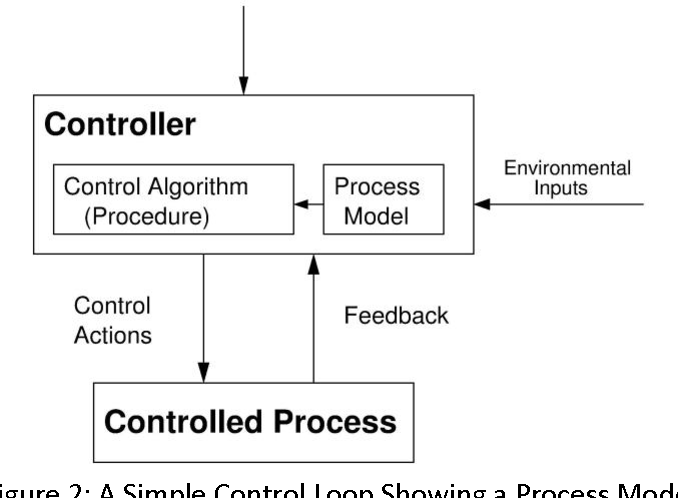

The concept of Aircraft Level Safety Assessment is introduced and the tools to accomplish this task are outlined. A failure such as a bad resistor arrp all flight control computers would be addressed here. The Functional Safety process is focused on identifying functional failure conditions leading to hazards.

No comments:

Post a Comment